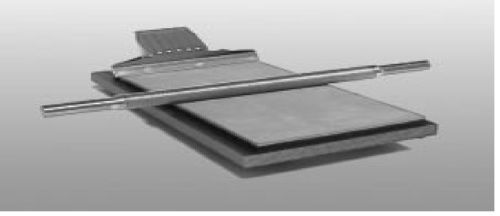

AUTOMATIC FILM APPLICATOR

5000 INR

Product Details:

- Power Source Electric (AC powered)

- Temperature Range Room temperature to 150C (depending on film / model specification)

- Automation Grade Automatic

- Accuracy 1%

- Voltage 220V / 110V (customizable)

- Frequency 50/60 Hz

- Measurement Range 0.01 mm to 5 mm (film thickness, depending on model)

- Click to view more

X

AUTOMATIC FILM APPLICATOR Price And Quantity

- 1 Piece

- 5000 INR

AUTOMATIC FILM APPLICATOR Product Specifications

- Motor, Electronic Controller, Film Applicator Head

- 0.01 mm to 5 mm (film thickness, depending on model)

- Adjustable coating speed, adjustable film thickness, programmable parameters, vacuum plate

- Digital LCD Display

- 50/60 Hz

- 220V / 110V (customizable)

- 1%

- Approx. 30 kg

- Automatic

- Uniform application of thin films/coatings on substrates

- Stainless Steel and Powder Coated Sheet Metal

- Room temperature to 150C (depending on film / model specification)

- Electric (AC powered)

- 500 mm x 350 mm x 280 mm

- Automatic Film Applicator

AUTOMATIC FILM APPLICATOR Trade Information

- 5-10 Piece piece Per Month

- 6-8 Week

Product Description

Features

- Accurate, consistent and repeatable draw down sampling.

- Eliminates ALL human variables speed, direction and rod pressure.

- Operator-friendly Touch Pad controls.

- Large, easy to read LED display indicates draw down speed.

- Speed is adjustable for 50 to 500mm per second.

- Wire bar attachment included as standard.

- Operate with wire bars and/or block spreaders/applicators.

Manual draw downs are often inconsistent especially between operators. This makes sample comparisons difficult or unreliable. The main factors affecting the draw down are the shear rate and downward force applied to the applicator tool.

Our automatic applicators use a precisely controlled beam to push a fixed gap applicator or wire wound bar applicator which traverses over the substrate at a selected speed and with constant downward force. Any standard applicator may be used.

| SKU | Name | |

|---|---|---|

| 1137 | Smaller size machine | |

| 1133N | As 1132N, but with built in vacuum bed | |

| 1132N | Standard Applicator with glass bed |

Versatile Film and Coating Application

This automatic applicator is engineered to uniformly apply thin films and coatings over diverse substrate materials, optimizing research and product development across multiple industries. With its precision stepper motor and integrated vacuum system, you can confidently achieve reproducible results with each coating cycle. The robust design is adaptable for glass, metals, plastic, and more, ensuring maximum compatibility and efficiency.

Intuitive Control and High Precision

The user-friendly touch panel or membrane keypad interface offers programmable parameters for precise control of film thickness and application speed. The digital LCD display provides clear real-time information, while accuracy is maintained at 1% and repeatability at a remarkable 0.01 mm. This ensures every application meets stringent quality criteria, ideal for materials testing and development laboratories.

FAQs of AUTOMATIC FILM APPLICATOR :

Q: How does the integrated vacuum pump benefit film application?

A: The integrated vacuum pump securely fixes the substrate in place during film application, preventing movement and ensuring uniform coating thickness across the entire surface. This results in improved precision and repeatability for each application cycle.Q: What is the process for adjusting coating thickness and speed?

A: Coating thickness and speed are easily adjusted using the touch panel or membrane keypad interface. You can set parameters and save them for repeat processes, with a measurement range from 0.01 mm up to 5 mm depending on the specific model selected.Q: Where can the AUTOMATIC FILM APPLICATOR be used?

A: This equipment is suitable for research laboratories, universities, industrial R&D departments, and production environments that require precise and uniform application of films on a variety of substrates, especially in India and international markets.Q: What substrates are compatible with this applicator?

A: The machine is compatible with glass, metal plates, plastic, paper, and film, enabling a wide range of applications in materials science, electronics, and surface coating research.Q: When should I use adjustable programmable parameters?

A: You should use adjustable programmable parameters whenever experiments require consistent and repeatable results or when testing various coating recipes, helping optimize efficiency in both research and industrial applications.Q: What are the main benefits of using this automatic film applicator?

A: Key benefits include high repeatability (0.01 mm), customizable working surfaces, fast setup, efficient power usage, and digital programmable controls. These features ensure accuracy, operational flexibility, and improved productivity.Q: How does temperature control work with the applicator?

A: The device is designed to operate at room temperature and, depending on the model, can manage films/coatings up to 150C. This broad range allows for application of heat-sensitive and temperature-cured coatings effectively.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese Get A Quote

Get A Quote