QUARTZ TUBE

Product Details:

- Accuracy High dimensional accuracy, typically 0.5mm

- Glass Type Fused Silica Quartz

- Temperature Resistance Up to 1100C (continuous), short term to 1250C

- Shape Cylindrical tube

- Features Excellent chemical resistance, high purity, high thermal shock resistance, UV and IR transmission

- Type Transparent Quartz Tube

- Dimension (L*W*H) Custom lengths and diameters available

- Click to view more

QUARTZ TUBE Price And Quantity

- 3 Piece

QUARTZ TUBE Product Specifications

- High-purity fused silica

- Custom lengths and diameters available

- Laboratory use, industrial heating, UV transmission, semiconductor, and photonics

- Transparent Quartz Tube

- Excellent chemical resistance, high purity, high thermal shock resistance, UV and IR transmission

- Cylindrical tube

- Quartz (SiO2, >99.99%)

- Up to 1100C (continuous), short term to 1250C

- Fused Silica Quartz

- Tube

- High dimensional accuracy, typically 0.5mm

QUARTZ TUBE Trade Information

- 3-4 Piece Per Day

- 3-4 Week

Product Description

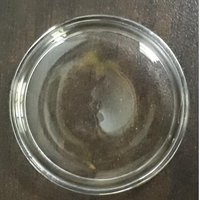

Quartz tube cap Inner diameter (D inner): min. 30, max. 31 mm

Thickness (d): 2.0 mm 0.5 mm

Height (H): min. 7 mm

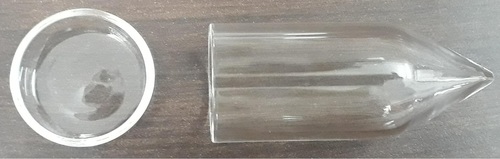

Quartz tube

Outer diameter (D outer): min. 27 mm, max. 28 mm

Inner diameter (Dinner): min. 25 mm, max. 26 mm

Thickness (d): 2.0 mm 0.2mm

Reference standard FDG600

Uv transmittance 190nm >=40

Uv transmittance 254nm >=87

Al 23.2ppm

Fe 4.8ppm

Ca 3.1ppm

Mg 2.5ppm

Li 2.0ppm

K 5.4ppm

Na 6.1ppm

Typical Physical Properties

Soften Point 1680C

Back light 1210C

Strain point 1120C

Density 2.2g/m

Hardness 5.5-6.5Mohs

Tensile strength 4.8 *10 TN/m2

compressive strength 1.1*109N/m2

Coefficient of thermal expansion (20-230C) 5.7*10-Tcm/cm.C

Heat conductivity(20C) 1.4w /m

specific heat 670J/kg.C

electrical resistivity 7*10-Tohm.cm

dielectric constant 3.75

insulating strength 5*107v/m

Exceptional Thermal Stability and Purity

Constructed from high-purity fused silica, these quartz tubes demonstrate outstanding resistance to thermal shock, enabling safe and reliable operation at continuous temperatures up to 1100C and short-term exposure to 1250C. This makes them suitable for demanding laboratory and industrial applications where both chemical purity and heat resistance are paramount.

Versatile Customization and Processing

With customizable dimensions and a choice of surface finishespolished or fire polishedthese quartz tubes can be precisely tailored using cutting, annealing, bending, and polishing techniques. They offer high dimensional accuracy (typically 0.5mm), ensuring a perfect fit for specialized equipment and processes across various scientific and industrial sectors.

Superior Optical and Chemical Performance

Exhibiting excellent light transmission (over 90% in the UV-visible range) and high resistance to acids, alkalis, and water, these quartz tubes excel in environments where both optical clarity and chemical durability are critical. UV-grade options are also available, making them ideal for use in photonics and UV transmission applications.

FAQs of QUARTZ TUBE:

Q: How are custom dimensions for quartz tubes specified and manufactured?

A: Custom quartz tubes can be manufactured to precise specifications by providing the required outer diameter, inner diameter, wall thickness, and length (up to 2000mm). Advanced processing methods such as cutting, bending, annealing, and polishing are used to achieve high dimensional accuracy, typically within 0.5mm.Q: What benefits do quartz tubes offer over other glass tubes in laboratory and industrial use?

A: Quartz tubes offer superior thermal resistance (up to 1100C continuous), exceptional chemical resistance to acids and alkalis, and excellent UV-visible light transmission (>90%). Their high purity ensures minimal contamination, making them ideal for sensitive applications in laboratories, photonics, and semiconductor industries.Q: When should UV-grade quartz tubes be selected for an application?

A: UV-grade quartz tubes should be chosen when applications demand high transmittance in the ultraviolet spectrum, such as photonics, UV curing, or analytical instrumentation. These tubes maintain excellent clarity and performance under UV exposure.Q: Where can transparent quartz tubes be used in industrial equipment?

A: Transparent quartz tubes are commonly utilized in equipment requiring high-temperature operation, such as industrial heaters, semiconductor processing equipment, UV sterilizers, and laboratory apparatus. Their clarity and chemical resistance make them suitable for gas and liquid transport or observation parts of reactors.Q: What is the process for ensuring high dimensional accuracy in quartz tubes?

A: High dimensional accuracy is achieved through precision cutting, controlled annealing, and polishing processes. Manufacturers adhere to strict quality standards (such as ISO 9001) to ensure each tube meets the specified tolerances, typically within 0.5mm.Q: How do quartz tubes retain their chemical resistance and optical clarity during use?

A: The high-purity fused silica composition of quartz tubes provides strong resistance to acids, alkalis, and water, preventing chemical degradation. Their excellent structural integrity maintains optical clarity and performance even after extended exposure to harsh environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese Get A Quote

Get A Quote