CT3 Texture Analyzer

Product Details:

- Sensor Type Load cell

- Measurement Range 0.01 to 50 kg

- Equipment Type Texture Analyzer

- Temperature Range 0C to 40C operating

- Connectivity Type USB interface for computer connectivity

- Capacity Up to 50 kg

- Frequency 50/60 Hz

- Click to view more

CT3 Texture Analyzer Price And Quantity

- 3 Piece

CT3 Texture Analyzer Product Specifications

- Load cell

- Texture Analyzer

- 0.01 to 50 kg

- 100-240V AC, 50/60Hz

- 50/60 Hz

- Up to 50 kg

- USB interface for computer connectivity

- 0C to 40C operating

- LCD display

- Stainless steel (sample platform), robust ABS housing

- 0.0001 kg

- 0.01 to 50 kg

- 25 W

- 20% to 90% RH (non-condensing)

- 0.5% full scale

CT3 Texture Analyzer Trade Information

- 3-4 Piece Per Day

- 3-4 Week

Product Description

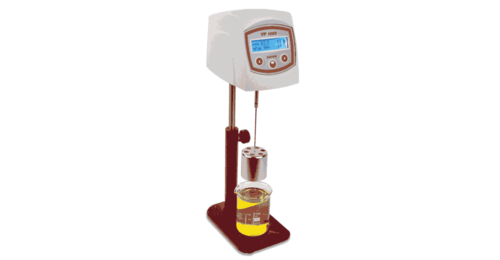

The CT3 is a low cost, but powerful, universal testing machine that offers both compression and tensile testing. It can calculate, through compression and tensile data, a number of physical properties that have proven to be highly correlated to human sensory evaluation of food and other consumer products. With six built-in test modes and ten memory slots for operator-protected tests with administrator rights, a wide choice of accessories and an optional software package, the CT-3 is perfect for most any physical testing requirements. The CT3 performs like a high end texture analyzer but at a fraction of the cost. Its uses can expand with your applications - or your testing imagination! The CT3's easy-to-operate design will have your R&D and QC up and running in no time.

Features & Benefits

- Choice of five load ranges up to 50kg

- A variety of probes and accessories for new application opportunities

- Choice of two adjustable base tables allows for for versatility of sample testing

- Six available test modes plus a calibration check

- Stores up to 10 additional customized test methods

- Easy-to-read display and easy-to-use, intuitive controls

- Provides a "real life" insight into physical properties

- Texture Profile Analysis (TPA) specific for the Food Industry

- USB and RS232 outputs

- Conforms fully with GME and GMIA monographs for gelatin Bloom assessment; includes built-in Bloom Test function

- Gelatin Bath System available for sample conditioning

- Easiest-to-use Texture Analyzer in its class

- Supplied with Texture Loader software to allow creation of up to 10 customized tests

- Can be used with optional software, TexturePro CT, to easily create custom reports and graphs

Typical Applications

Non-Food Applications

- Adhesives

- Asphalt

- Candles

- Cosmetics

- Creams

- Detergent

- Foams

- Grease

- Gum

- Packaging

- Paint

- Personal Care

- Polymers

- Rubber Sealants

- Silicone

- Soap

- Sponges

- Wax

Food Applications

- Biscuits

- Bread

- Butter

- Cakes

- Candies

-

- Cheese

-

- Chocolate

- Confectionery

- Cookies

- Crackers

- Fruits

- Gels/Gelatin

- Margarines

- Meat Products

- Pet Foods

- Pudding

- Sauces

- Snack Foods

- Spread

- Starch

- Surimi

Parameters Measured

- Elasticity

- Hardness

- Cohesiveness

- Burst Strength

- Breaking Point

- Fracturability

- Gel Strength

- Ripeness

- Yield Point

- Spreadability

- Tackiness

- Consistency

- Relaxation

- Pliability

- Adhesiveness

- Firmness

Highly Adaptable Measurement Modes

The CT3 Texture Analyzer provides multiple test modes, including tension, compression, cycle, and hold, allowing users to perform a wide range of texture analyses on different sample types. Its ability to process various materials improves workflow flexibility in laboratories and production quality control.

User-Friendly Software Integration

With its included Windows-based software and USB connectivity, the CT3 enables effortless data acquisition and analysis. Results can be exported directly to a PC or printer, streamlining reporting. The LCD display further simplifies on-site operation and monitoring.

Robust Construction and Safety Features

Engineered from sturdy ABS materials with a stainless steel sample platform, the CT3 is built for longevity. Advanced safety measures such as auto-stop and overload protection help safeguard both operators and samples during testing.

FAQs of CT3 Texture Analyzer:

Q: How does the CT3 Texture Analyzer ensure accurate measurements during texture analysis?

A: The CT3 Texture Analyzer utilizes a high-precision load cell sensor and offers a resolution of 0.0001 kg with an accuracy of 0.5% full scale. Its advanced software and calibrated system enable reliable and repeatable measurements across its test range of 0.01 to 50 kg.Q: What types of tests can be performed with the CT3 Texture Analyzer, and what are their benefits?

A: Users can conduct tension, compression, cycle, and hold tests, providing a comprehensive assessment of material properties. These modes allow for versatile analysisfrom measuring firmness and flexibility to evaluating adhesive or breaking strengthbenefiting quality control and product development.Q: When is the best time to use the CT3 Texture Analyzer in a production or laboratory setting?

A: The CT3 should be used during product development, quality assurance, and routine texture analysis of raw materials, intermediates, or finished products. Its quick setup and multiple fixtures make it ideal for frequent testing and sample comparisons.Q: Where can data from the CT3 Texture Analyzer be accessed or exported for reporting?

A: Test results from the CT3 can be exported directly to a PC or printed using the built-in USB interface and Windows-based software. This direct data output supports seamless integration into digital laboratory records or quality assurance databases.Q: What is the process for using the CT3 Texture Analyzer with different samples and probes?

A: The CT3 comes with a variety of probes and fixtures. After selecting the appropriate accessory for the sample type, users install it, configure test parameters via software or the LCD display, and execute the analysis. The auto-stop and overload protection features help maintain safe operation throughout the process.Q: How does the CT3 Texture Analyzer benefit manufacturers and suppliers in India?

A: By offering consistent, high-accuracy texture measurements, the CT3 helps manufacturers and suppliers maintain product standards and comply with regulatory requirements. Its adaptability and robust construction cater to diverse sectors, promoting competitive quality management nationally and internationally.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese Get A Quote

Get A Quote