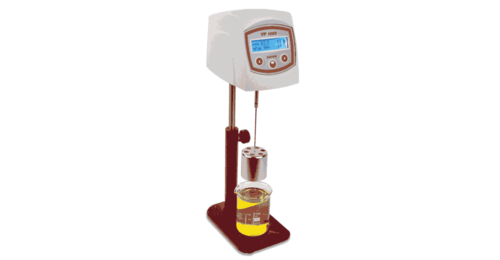

KV100 Capillary Viscometer

1000 INR/Piece

Product Details:

- Capacity 100 ml

- Equipment Type Capillary Viscometer

- Sensor Type Digital Temperature Sensor

- Frequency 50 Hz

- Humidity % Up to 90% RH, non-condensing

- Connectivity Type RS232 Interface

- Resolution 0.01 mm/s

- Click to view more

X

KV100 Capillary Viscometer Price And Quantity

- 100.00 - 1000.00 INR/Piece

- 1000 INR/Piece

- 3 Piece

KV100 Capillary Viscometer Product Specifications

- Capillary Viscometer

- Digital Temperature Sensor

- 100 ml

- 0.2%

- 0.3 to 600 mm/s

- Up to 90% RH, non-condensing

- 230 V AC, 50 Hz

- 50 Hz

- Digital LCD Display

- Stainless Steel with Glass Capillary

- 0.01 mm/s

- Ambient to 150C

- RS232 Interface

- Less than 100 W

- Atmospheric

- 0.3 to 600 mm/s

KV100 Capillary Viscometer Trade Information

- MUMBAI

- 3-4 Piece Per Day

- 3-4 Week

- All India

- ISO CERTIFICATE : 9001:2015

Product Description

Model KV100 is a user-friendly capillary viscometer which operates excellent in rough process environments, on downgraded set-ups at pilot plants, as well as under semi-laboratory conditions.

The KV100 Capillary Viscometer easily measures low and medium viscosity materials. Based on the principle that the pressure decrease between the two ends of the measuring capillary is proportional to viscosity a permanent control signal is determined.

Features And Benefits

- Continuous measurement eliminates need for "Grab" sampling and allows for prediction and constant control of final product properties

- The gear pump forced internal sample flow via magnet coupling keeps the instrument resistant to pressure and temperature

- 4-20 mA output signal provides a variety of display and control capabilities

- Sample transport by aspiration tube into the viscometer creates bypass situation where measurement "Zone" is protected from main flow, allowing accurate, repeatable measurement under variable conditions

- Availability of various standard viscosity ranges up to 500 mPas (cP); customized ranges on request

- Display device for measuring data including calculation options

Specifications

| Viscosity Range: | 0 to 500 mPas (cP) |

| Temperature: | -25°C to +140°C |

| Maximum Pressure: | 25 bar (360 psi) |

| Input Power: | 230 V AC, 50/60 Hz; 24 V DC |

| Output: | 4 - 20 mA |

Options

- ATEX approved design for explosion-proof requirements

- Mounts in-line supported by stainless steel flow chambers with customized flange connections

- Special synthetic material-based flow chambers for small pipe diameters or tube connections

- Flange for tank or container mounting

- Temperature compensation of viscosity reading

Exceptional Temperature Control

Enjoy unmatched temperature consistency with the KV100s high-precision immersion heater and digital temperature sensor. The system ensures stability within 0.01C, vital for maintaining accurate kinematic viscosity measurements across various liquid samples, enhancing reliability and repeatability in results.

Supports Multiple Capillary Types

The KV100 supports a wide array of capillary tubes, including BS/IP/UBBLEOHDE, OSTWALD, REDWOOD, and CANNON-FENSKE. This compatibility offers flexibility to users conducting tests as per diverse industry standards and applications, making it suitable for both research and analytical laboratories.

User-Friendly Semi-Automatic Operation

Equipped with a digital timer with memory backup and a digital LCD display, the viscometer streamlines routine measurements. The magnetic stirrer ensures homogenous temperature within the bath, while safety mechanisms provide peace of mind during extended operation.

FAQs of KV100 Capillary Viscometer:

Q: How does the KV100 Capillary Viscometer ensure accurate viscosity measurements?

A: The KV100 uses a constant temperature bath regulated by a high-precision immersion heater and a digital temperature sensor, which maintains thermal stability to within 0.01C. This consistent environment, combined with a magnetic stirrer for uniform fluid temperature, minimizes measurement variability, ensuring reliable and reproducible results.Q: What types of capillaries can be used with this viscometer?

A: This instrument is compatible with BS/IP/UBBLEOHDE, OSTWALD, REDWOOD, and CANNON-FENSKE capillaries. Such wide support allows users to select the appropriate tube based on their specific testing requirements and international standards.Q: When is it ideal to use the KV100 Capillary Viscometer?

A: The KV100 is best suited for laboratory environments requiring precise kinematic viscosity measurements of both transparent and opaque liquids, particularly when conformity to ASTM D445 is crucial. Its robust design and precision make it suitable for routine quality control as well as advanced research.Q: Where can this viscometer be employed?

A: Ideal for industrial, research, and QC laboratories, the KV100 can be found in petrochemical plants, universities, pharmaceutical companies, and other facilities in need of viscosity analysis. Its adherence to key standards makes it a trusted tool across various sectors.Q: What is the sample handling process for viscosity determination?

A: To measure viscosity, a minimum sample volume of 20 ml is introduced into the compatible capillary. The bath temperature is set according to the testing method, and the digital timer initiates measurement as the sample flows through the capillary, enabling automated, precise timing and digital result display.Q: How does the built-in memory backup benefit users during testing?

A: The digital timers memory backup ensures that measurement data and timing remain intact during power interruptions or accidental shutdowns. This safeguards test continuity and reduces the chance of data loss, contributing to greater operational efficiency.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese Get A Quote

Get A Quote