NACHTF - High Temperature Laboratory Chamber Furnaces

5000 INR

Product Details:

- Temperature Range Ambient to 1700C

- Frequency 50/60 Hz

- Capacity Multiple options; commonly 5L, 10L, 15L, 20L

- Feature Uniform temperature distribution, over-temperature protection, rapid heating

- Accuracy 1C

- Model No NACHTF

- Measurement Range Suitable for thermal processing up to 1700C

- Click to view more

X

NACHTF - High Temperature Laboratory Chamber Furnaces Price And Quantity

- 1 Piece

- 5000 INR

NACHTF - High Temperature Laboratory Chamber Furnaces Product Specifications

- Semi-automatic

- Approximately 32 kg (varies by model)

- Heating elements, digital controller, chamber insulation

- High temperature laboratory heating, sintering, ashing, material testing

- Electric

- Ceramic fiber insulation, Mild steel outer body, Kanthal heating elements

- Digital controller with LED display

- NACHTF

- 1C

- Varies with capacity; sample model: 400 x 350 x 480 mm

- Suitable for thermal processing up to 1700C

- 230V AC / 240V AC

- Multiple options; commonly 5L, 10L, 15L, 20L

- Ambient to 1700C

- 50/60 Hz

- Laboratory Chamber Furnace

- Uniform temperature distribution, over-temperature protection, rapid heating

NACHTF - High Temperature Laboratory Chamber Furnaces Trade Information

- 5-10 Piece piece Per Month

- 6-8 Week

Product Description

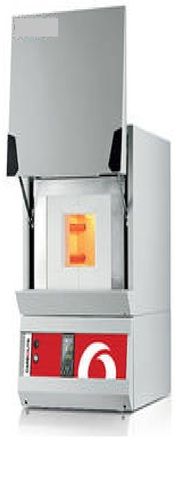

The NACHTF high temperature chamber furnace range comprises

1700 °C and 1800 °C models.

There are two bench-top sized chambers for each of the maximum temperatures, together with larger capacity floor standing units with capacities in excess of 15 litres.

The two smaller models in each temperature are bench mounted and the larger units are floor-standing. These furnaces may be customised in order to satisfy specific customer requirements, eg the addition of catalytic afterburners for ceramic binder burn-off applications.

Standard Features

- 1700°C & 1800°C maximum operating temperature

- From 4 to 27 litre capacities

- High quality molybdenum disilicide heating elements

- Up & away door keeps heated surface away from the user

- Advanced refractory interior, used in combination with energy efficient low thermal mass insulation

- Programmable 3216P1 controller

- Over-temperature protection

- Digital RS232 communications on the following models: HTF 17/5, HTF 17/10, HTF 18/4 & HTF 18/8

- Fan cooling for low external case temperature

- The RHF 17/25 & HTF 18/15 both have electric door actuation

Options (specify these at time of order)

- A range of sophisticated digital controllers, multi-segment programmers and data loggers is available. These can be fitted with RS232, RS485 or Ethernet communications

- RS232 & RS485 communications (RHF17/25, HTF18/15 & HTF18/27)

Control Options

- 3216 Programmable Controllers

- 3508 Programmable Controllers

Content may be subject to modifications or corrections

Superior Thermal Efficiency for Laboratory Precision

NACHTF furnaces utilize high purity ceramic chambers and dense ceramic fiber insulation (up to 75 mm thick), ensuring exceptional thermal stability and energy efficiency during intense laboratory operations. The advanced Kanthal heating elements and uniform heat distribution support reliable results across numerous scientific processes, including material evaluation and heat treatments.

Comprehensive Safety and Control Features

Engineered for safety, the NACHTF is equipped with a front-loading insulated door featuring a safety switch, over-temperature cut-off, and a PID microprocessor controller for accurate settings. The rugged exterior is powder-coated and rust-resistant, while low surface temperatures protect laboratory operators.

Flexible Design and Application Versatility

Available in multiple chamber sizes (5L, 10L, 15L, 20L), the NACHTF is suitable for benchtop or free-standing installation in well-ventilated, indoor laboratory environments. Optional accessories, like programmable controllers, data loggers, and exhaust vents, enable further customization for specific experimental needs or compliance standards.

FAQs of NACHTF - High Temperature Laboratory Chamber Furnaces:

Q: How does the NACHTF furnace ensure uniform temperature distribution during operation?

A: The NACHTF furnace features high purity ceramic chambers and Kanthal heating elements working in tandem to deliver even heat distribution. Combined with up to 75 mm thick ceramic fiber insulation, this design ensures exceptional uniformity, essential for precise laboratory procedures.Q: What safety mechanisms are incorporated in the NACHTF furnace?

A: For operator safety, the furnace is equipped with an over-temperature cut-off, a safety interlocked insulated front door, and a specially designed low exterior surface temperature. These features help prevent accidental exposure to high temperatures and provide reliable protection in the laboratory setting.Q: When is the ideal environment for installing an NACHTF chamber furnace?

A: The NACHTF furnace should be operated indoors in a well-ventilated laboratory space. Placement on a benchtop or as a free-standing unit allows flexibility, and proximity to power (230/240V AC) is necessary for proper installation and use.Q: Where can the NACHTF chamber furnace be applied most effectively?

A: This high temperature furnace excels in applications such as ashing, ceramics processing, metal heat treatment, sintering, and general material testing in research laboratories, metallurgy units, and educational facilities.Q: What process controls and monitoring does the NACHTF offer?

A: The built-in PID microprocessor-based controller manages heating processes accurately, allowing users to select temperature, heating rate (standard 8C/min, customizable), and view real-time data via an LED digital display. Optional additions like a programmable controller and data logger provide enhanced control and recording.Q: How does using the NACHTF furnace benefit laboratory productivity?

A: With rapid, uniform heating and robust safety features, the NACHTF minimizes downtime and risk. Its customizable options and accurate temperature maintenance up to 1700C facilitate a wide variety of experiments while ensuring both efficiency and operator safety.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese Get A Quote

Get A Quote