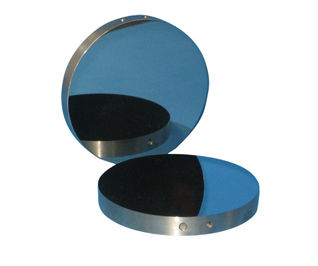

4" Diameter 316SS Polymer Film Pressing Platens

Product Details:

- Material 316 Stainless Steel (316SS)

- Dimension (L*W*H) Diameter: 4 inches (approx. 101.6 mm); Thickness: 20 mm (typical)

- Application Pressing and forming polymer films; Laboratory sample preparation

- Accessories None (platens only; press sold separately)

- Click to view more

4" Diameter 316SS Polymer Film Pressing Platens Price And Quantity

- 3 Piece

4" Diameter 316SS Polymer Film Pressing Platens Product Specifications

- Diameter: 4 inches (approx. 101.6 mm); Thickness: 20 mm (typical)

- None (platens only; press sold separately)

- Pressing and forming polymer films; Laboratory sample preparation

- 316 Stainless Steel (316SS)

4" Diameter 316SS Polymer Film Pressing Platens Trade Information

- 3-4 Piece Per Day

- 3-4 Week

Product Description

The 4" diameter polished platens are useful for making large diameter polymer films. The platens are made from 1/2" thick 316SS. Platen surfaces are polished to a mirror finish or are available lapped flat to a finely honed matte finish. Matte finish platens are useful for limiting fringing of polymer films which take on the surface characteristics of the platens against which they are pressed. There are ports in the platens to enable insertion of a thermocouple probe. The platens are also tapped with a female thread to allow attachment of an optional handle. Optional spacers to contain polymer samples are available in thicknesses and diameters specified by the customer. The platens are compatible with our standard heated platens (43212-6664).

| Part No. | Description |

| 43212-8486 | Pair (2) polished 4" diameter 316SS Platens |

| 43212-9104 | Pair (2) of matte finish finely lapped 4" diameter 316SS Platens |

| 43212-9106 | Heated platens (43212-6664) with matte finish 316SS film pressing platens (43212-9104) with handles (43212-8591) and temperature controller |

| 43212-8591 | Optional Handles Pair (2) |

| 43212-6664 | Heated Platens with Temperature Controller |

Superior Polymer Film Release

The platens mirror-polished finish dramatically reduces adhesion between the platen and polymer films, promoting effortless release after pressing. This feature not only speeds up sample preparation in laboratories but also preserves the integrity of delicate polymer films, making the platens an ideal tool for researchers and manufacturers focused on high-precision film quality with minimal wastage.

Durable, High-Temperature Performance

Constructed from premium 316 stainless steel, these platens withstand rigorous operating conditions, enduring up to 400C continuous heat exposure. Their outstanding corrosion resistance assures consistent longevity, even under aggressive laboratory environments or frequent temperature cycling, ensuring reliable and repeatable polymer pressing every time.

Versatile and User-Friendly Integration

With their universal 4-inch diameter and chamfered edge design, the platens are compatible with both manual and hydraulic press systems commonly used in laboratories and manufacturing settings. Simple to install, these platens facilitate various pressing and shaping assignments, making them suitable across research and industrial applications where precision and surface integrity are paramount.

FAQs of 4" Diameter 316SS Polymer Film Pressing Platens:

Q: How are these 4" platens typically used in polymer film preparation?

A: These platens are primarily used for pressing and forming polymer films in laboratory environments. Their mirror-polished surface aids in consistent film thickness and easy removal after pressing, making them suitable for sample preparation and analytical studies.Q: What is the main benefit of the mirror-polished surface finish?

A: The mirror-polished finish significantly enhances film release, reducing the risk of the polymer sticking or tearing upon removal. This results in cleaner, more uniform films and minimizes the likelihood of sample loss or contamination.Q: When should 316SS platens be chosen over standard steel alternatives?

A: 316 stainless steel platens should be selected when applications require high corrosion resistance, exposure to aggressive chemicals, or temperatures up to 400C. Their durability and longevity make them preferable for rigorous laboratory or industrial tasks.Q: Where can these platens be incorporated, and with which press types are they compatible?

A: These platens are designed for use with standard manual and hydraulic laboratory presses. Their dimensions and edge design allow them to fit common press setups used for polymer processing or sample preparation.Q: What is the process for maintaining and cleaning these platens?

A: Routine cleaning with mild solvents or detergents is recommended to preserve the mirror-finish and avoid surface abrasion. Avoid using abrasive pads that might damage the polished surface. Allow platens to cool before handling and cleaning after high-temperature use.Q: How does the chamfered edge contribute during pressing operations?

A: Chamfered edges on the platens help reduce tearing or damage to thin polymer films during pressing, particularly near the platen boundaries. This design ensures a smoother film edge and more consistent sample results.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese Get A Quote

Get A Quote