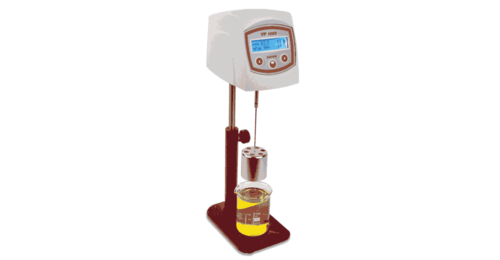

BROOKFIELD KV-200 VISCOMETER

Product Details:

- Frequency 50/60 Hz

- Resolution 0.01 cP

- Connectivity Type RS232 Interface

- Capacity Standard sample volume: 250500 ml

- Pressure Range Atmospheric

- Material Stainless Steel & ABS Plastic

- Power Supply 220V AC, 50Hz

- Click to view more

X

BROOKFIELD KV-200 VISCOMETER Price And Quantity

- 3 Piece

BROOKFIELD KV-200 VISCOMETER Product Specifications

- 220V AC, 50Hz

- Standard sample volume: 250500 ml

- 30 W

- RS232 Interface

- Digital LCD

- Stainless Steel & ABS Plastic

- Atmospheric

- 1% of full scale

- 50/60 Hz

- 0.01 cP

BROOKFIELD KV-200 VISCOMETER Trade Information

- 3-4 Piece Per Day

- 3-4 Week

Product Description

Features And Benefits

- Continuous measurement eliminates need for "Grab" sampling and allows for prediction and constant control of final product properties

- The gear pump forced internal sample flow via magnet coupling keeps the instrument resistant to pressure and temperature

- 4-20 mA output signal provides a variety of display and control capabilities

- Sample transport by aspiration tube into the viscometer creates bypass situation where measurement "Zone" is protected from main flow, allowing accurate, repeatable measurement under variable conditions

- Availability of various standard viscosity ranges up to 500 mPas (cP); customized ranges on request

- Display device for measuring data including calculation options

Specifications

| Viscosity Range: | 0 to 500 mPas (cP) |

| Temperature: | -25°C to +140°C |

| Maximum Pressure: | 25 bar (360 psi) |

| Input Power: | 230 V AC, 50/60 Hz; 24 V DC |

| Output: | 4 - 20 mA |

Precision Performance for Reliable Results

The BROOKFIELD KV-200 VISCOMETER is engineered to deliver high accuracy and repeatability, meeting stringent ASTM and ISO standards. Its robust spindles and wide speed range provide dependable results, whether for research or production quality assurance. The digital LCD and auto-ranging display make readings straightforward, enhancing efficiency and productivity in viscosity testing.

Flexible Connectivity and Easy Operation

Equipped with an RS232 interface, this viscometer easily connects to computers or printers for seamless data management. Its intuitive controls allow for quick speed selection and spindle changes, minimizing downtime during measurements. The adjustable, rigid stand ensures secure mounting, making it suitable for frequent laboratory or industrial use.

FAQs of BROOKFIELD KV-200 VISCOMETER:

Q: How do I select the appropriate spindle and speed range for my sample with the KV-200 Viscometer?

A: To choose the correct spindle and speed, consider your samples expected viscosity; use lower-numbered spindles and/or lower speeds for low-viscosity samples, and higher-numbered spindles or higher speeds for thicker samples. Refer to the user manual for guidance on matching spindle and speed settings to your samples viscosity range.Q: What type of data output options does the BROOKFIELD KV-200 provide?

A: The KV-200 Viscometer features direct connectivity to computers and printers via its RS232 interface, allowing for convenient data recording, transfer, and analysis. This facilitates integration with laboratory information management systems or on-the-spot printing of viscometry results.Q: When is calibration or verification of the viscometer recommended?

A: Calibration or verification should be performed periodically based on usage frequency, typically every 6 to 12 months, or whenever measurement consistency is in question. For best results, use certified calibration fluids and follow ASTM or ISO procedures as specified in the manual.Q: Where can the BROOKFIELD KV-200 Viscometer be installed and operated?

A: This viscometer is designed for use in laboratories, industrial facilities, and quality control environments in India or globally. It operates best in environments with temperatures between 1535C and humidity up to 80% RH, ensuring stable and accurate measurements.Q: What is the process for connecting the KV-200 to a computer or printer?

A: Simply connect the device to your computer or printer using the RS232 interface cable. Ensure compatible software is installed on your computer for direct data transfer or printing functionality, as described in the product documentation.Q: How does the digital LCD and auto-ranging display enhance usability?

A: The digital LCD with auto-ranging allows for precise, at-a-glance readings down to 0.01 cP. This feature simplifies result interpretation, reduces error, and streamlines the process of recording and analyzing viscosity measurements.Q: What are the main benefits of choosing the BROOKFIELD KV-200 Viscometer for your lab or production line?

A: Key advantages include high measurement accuracy and repeatability, compliance with international standards, effortless data connectivity, and robust construction suitable for demanding laboratory or industrial environments. This makes it an excellent choice for organizations requiring reliable viscosity measurements.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese Get A Quote

Get A Quote