Mini Pellet Press

Product Details:

- Feature Compact design, easy operation

- Temperature Range Ambient to 300C

- Core Components Die Set, Pressing System

- Automation Grade Semi-Automatic

- Power Source Electric

- Accuracy 1C

- Capacity 5-10 pellets per batch

- Click to view more

Mini Pellet Press Price And Quantity

- 5000 INR

- 1 Piece

Mini Pellet Press Product Specifications

- Semi-Automatic

- Die Set, Pressing System

- Ambient to 300C

- Compact design, easy operation

- 5-10 pellets per batch

- 1C

- Laboratory sample pelletizing

- Electric

- 150 mm x 130 mm x 300 mm

- Digital

- Manual and Semi-Automatic

- 1-15 mm pellet diameter

- MPP-05

- Approx. 15 kg

- Stainless Steel & Alloy Steel

- 50/60 Hz

- 220-240V

Mini Pellet Press Trade Information

- 5-10 Piece piece Per Month

- 6-8 Week

Product Description

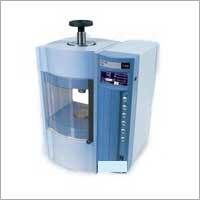

Mini Pellet Press

Hydraulic Press for 7mm Pellets

The Mini-Pellet Press is an entry-level laboratory hydraulic press for the preparation of high-quality 7mm KBr pellets for transmission FTIR analysis. With a rugged and durable design, this press is intended for regular laboratory use with maintenance-fee operation.

Mini-Pellet Press is designed to be used on a laboratory bench top, but is small in size and light enough in weight to allow it to be moved to different points of use or stored when not required. Full hydraulic operation, and an innovative sealed hydraulic unit, allows the user to apply the required load for sample preparation through the simple rotation of a load knob. Reproducible load for pressing high-quality KBr pellets suitable for quantitative studies is facilitated by use of integrated pressure gauge.

The Mini-Pellet Press is also available as part of a Basic Solid Pack. This pack is equipped with a range of sample preparation components necessary for FTIR solid sample analysis by transmission, including: the Mini-Pellet Press, a 7mm Pellet Die Assembly, 7mm Disc Holder for a standard 3 by 2 mount, a pair of spare Pellet Ring Holders, a Pestle and Mortar, and KBr Powder (50g).

Features and Benefits

Precision and Versatility for Laboratory Applications

The Mini Pellet Press offers exceptional precision with a wide pellet diameter range of 1 to 15 mm. Its design caters to the demands of laboratory environments handling chemical, pharmaceutical, and materials science samples. With low power consumption and a reliable powder-coated body, this press balances performance and efficiency for daily sample preparation.

User-Friendly Operation and Enhanced Safety

Equipped with integrated electronic controls, digital display, and a semi-automatic press system, the MPP-05 simplifies the pelletizing process. The overload protection mechanism ensures safe operation, while components are easy to maintain and clean, making this equipment ideal for continuous laboratory use.

Compact Design, Robust Construction

The Mini Pellet Press is built with stainless and alloy steel, weighing approximately 15 kg. Despite its sturdy construction, its compact form factor (150 x 130 x 300 mm) allows for convenient placement and mobility within laboratory setups, supporting efficiency without occupying significant workspace.

FAQs of Mini Pellet Press:

Q: How does the Mini Pellet Press ensure accurate and consistent pellet sizes?

A: The Mini Pellet Press uses hardened stainless steel die sets and an integrated electronic control panel with a digital display to manage all pressing parameters. This ensures each pellet falls within the measurement range of 115 mm diameter with an accuracy of 1C, delivering consistent results.Q: What is the process for operating the Mini Pellet Press?

A: To operate, load the desired sample into the die set and select your preferred settings using the integrated control panel. The device supports manual hydraulic pressing with electric boost, and the process can be monitored via the digital display. Overload protection assures safe operation throughout the pressing cycle.Q: When is it suitable to use the Mini Pellet Press for sample preparation?

A: The press is specifically designed for laboratory settings in the chemical, pharmaceutical, and material science fields. It is ideal when accurate, small batch sample pelletizing is required for research, analysis, or quality control purposes.Q: Where can this pellet press be effectively installed in a lab?

A: With a compact footprint of 150 x 130 x 300 mm and a weight of about 15 kg, it can be installed on standard laboratory worktops or benches. Its portability and robust build make it suited to most laboratory environments across India and globally.Q: What are the primary benefits of using the MPP-05 Mini Pellet Press?

A: The main benefits include high precision in pellet diameter, easy operation, low maintenance, quick cleaning, enhanced safety through overload protection, and quiet performance. Its semi-automatic design also improves workflow efficiency for laboratory technicians.Q: How much sample can the press handle per batch, and what is its output capacity?

A: The Mini Pellet Press can process 510 pellets per batch, with each pellet weighing up to 5 grams. This allows efficient preparation of multiple samples in a single operation while maintaining consistent quality.Q: Is the Mini Pellet Press easy to maintain and clean between uses?

A: Yes, the press is designed with easy-to-clean components and a powder-coated surface finish. Routine maintenance is minimal, ensuring that cleaning between sample types remains quick and convenient, reducing downtime in the laboratory.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese Get A Quote

Get A Quote