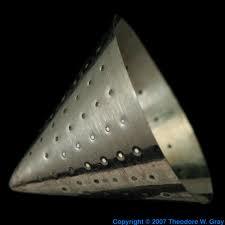

Platinum Parting Tray

5000 INR/Piece

Product Details:

- Power Supply Not Required

- Shape Rectangular or as per requirement

- Temperature Resistance Up to 1700C

- Glass Type Compatible with Borosilicate & Silicate Glass

- Type Parting Tray

- Dimension (L*W*H) Customizable, standard size available up to 400x200x30 mm

- Equipment Materials Platinum or Platinum Alloy

- Click to view more

X

Platinum Parting Tray Price And Quantity

- 5000 INR/Piece

- 1 Piece

Platinum Parting Tray Product Specifications

- Customizable, standard size available up to 400x200x30 mm

- Platinum or Platinum Alloy

- Parting Tray

- Varies, typically up to 2.5 L

- Compatible with Borosilicate & Silicate Glass

- Up to 1700C

- High purity Platinum

- Rectangular or as per requirement

- Glass melting, precious metal handling, laboratory and industrial applications

- Not Required

- Not Required

Platinum Parting Tray Trade Information

- MUMBAI

- Cash Advance (CA), Telegraphic Transfer (T/T), Cash in Advance (CID)

- 5 Piece Per Month

- 3-4 Week

- Australia, South America, Western Europe, Middle East, Central America, Africa, Asia, Eastern Europe, North America

- All India

- ISO CERTIFICATION

Product Description

Parting Tray is utilized for analysis of Gold Samples. It is made out of the Alloy with composition of pure metal

of purity 99.95% of metals with composition platinum / 5% or 10% of tray & handle and the cuples (cups) of

pure platinum or 2% alloy of Pt-Ir. The tray are avaliable in the various size with 4, 16, 24 & 36 cuples and its

corresponding weights are:

| No. | cuples | Weight (gram) |

| NAC 148A | 04 | 050.000 / 060.000 |

| NAC 148B | 16 | 110.000 / 125.000 |

| NAC 148C | 24 | 170.000 / 190.000 |

| NAC 148D | 36 | 275.000 / 300.000 |

Exceptional Purity and Thermal Stability

Fabricated from high-purity 99.95% platinum, this parting tray ensures negligible contamination and optimal durability, even under continuous exposure to temperatures as high as 1650C. Its unmatched chemical inertness allows safe contact with strong acids and oxidants without degradation.

Customization for Versatile Applications

The tray supports full customizationchoose dimensions, thickness, or alloy constituents to suit your specific operations. Alongside standard sizes up to 400x200x30 mm, this flexibility meets the requirements of scientific research, manufacturing, and glass industries.

Reliable for Critical Processes

Designed for precise parting or separation in crucible and glass-handling tasks, this tray aids in efficient workflows. Its robust construction resists deformation under rapid heating or cooling cycles, guaranteeing repeatable performance in both laboratory and industrial applications.

FAQs of Platinum Parting Tray:

Q: How is the Platinum Parting Tray used in laboratory and glass melting operations?

A: The Platinum Parting Tray is primarily utilized to facilitate the separation or parting of materials in platinum crucibles during glass melting, precious metal handling, and laboratory procedures. Its inert nature and high thermal resilience allow for safe and thorough processing of samples exposed to extreme temperatures and aggressive chemicals.Q: What customization options are available for the Platinum Parting Tray?

A: You can customize the trays dimensions, thickness, shape (rectangular or as required), and alloy composition. While standard sizes are available up to 400x200x30 mm, bespoke configurations are offered to match specific industrial or laboratory needs, ensuring optimal fit and function.Q: When is it beneficial to use a Platinum Parting Tray in processing?

A: It is especially advantageous to use a Platinum Parting Tray during operations that involve high temperatures, aggressive chemicals, or the need for inert environments. It is suitable for glass melting, handling of precious metals, and research processes where maximum purity and reliability are demanded.Q: Where is the Platinum Parting Tray manufactured and who can source it?

A: This tray is manufactured in India, and is available for global export and import. Its accessible to manufacturers, suppliers, traders, and research institutions seeking reliable solutions for critical glass and metal processes.Q: What makes platinum or its alloy ideal for this type of tray?

A: Platinum and its alloys are chosen for their outstanding chemical inertness, high temperature endurance, and mechanical stability. This ensures the tray does not react with most acids and oxidants, maintains structure at elevated temperatures, and guarantees longevity in repeated cycles.Q: How does the design of the tray benefit laboratory and industrial workflows?

A: The robust and customizable design allows for seamless integration into existing systems, enhances workflow efficiency, and minimizes process contamination. It provides consistent arrangement and safe handling of materials under rigorous laboratory or industrial conditions.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese Get A Quote

Get A Quote