Reconditioning HATR Plates

5000 INR

Product Details:

- Feature Restores plate efficiency, removes fouling, corrects plate deformation

- Frequency On Demand / As required

- Capacity As per requirement (Customized)

- Temperature Range Up to 600C (depending on plate material)

- Core Components HATR Plates, Sealing Gaskets (if applicable)

- Power Source Industrial No direct electrical consumption (Mechanical & Chemical process)

- Equipment Materials Stainless Steel, Mild Steel, as per application

- Click to view more

X

Reconditioning HATR Plates Price And Quantity

- 5000 INR

- 1 Piece

Reconditioning HATR Plates Product Specifications

- Stainless Steel, Mild Steel, as per application

- Heat Exchanger Plate Reconditioning Service

- Industrial No direct electrical consumption (Mechanical & Chemical process)

- Up to 600C (depending on plate material)

- Varies according to plate size and material

- As per clients supplied plate dimensions

- As per requirement (Customized)

- Restores plate efficiency, removes fouling, corrects plate deformation

- On Demand / As required

- HATR Plates, Sealing Gaskets (if applicable)

Reconditioning HATR Plates Trade Information

- 5-10 Piece piece Per Month

- 6-8 Week

Product Description

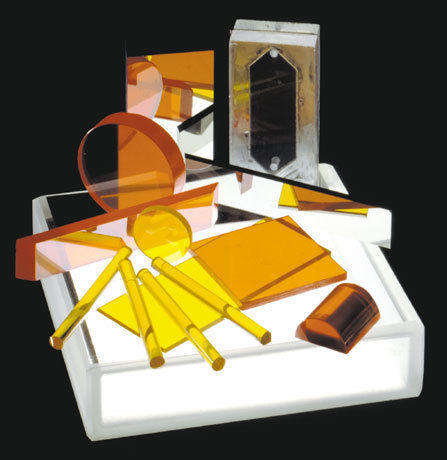

HATR Prisms can frequently be reconditioned inexpensively, sometimes without even removing them from the HATR top plate. Send us your HATR top plate for evaluation.

ATR Internal Reflection Plate Repolishing | |||||||||||||

STANDARD SIZE

|

| ||||||||||||

ATR PLATES

|

| ||||||||||||

HATR PLATES |

| ||||||||||||

Comprehensive Plate Restoration

Our service covers the full spectrum of reconditioning needs for HATR Plates, from surface finishing (polished or brushed) to flattening deformed plates. Whether suffering from fouling, surface warping, or corrosion, each plate is individually assessed and treated with industry-compliant processes, ensuring suitability for demanding applications.

Tailored for Diverse Industries

We serve critical sectors such as Chemical, Pharmaceutical, Oil & Gas, and Fertilizer by customizing our reconditioning solutions to meet unique requirements. With capacity and dimensions tailored to client-supplied specifications, we help firms across these industries optimize their heat exchanger performance and maintain rigorous operational standards.

Maximized Longevity and Efficiency

By restoring surface flatness, removing contaminants, and reinforcing corrosion resistance, our service ensures that every reconditioned HATR plate delivers prolonged service life and improved energy efficiency. Clients benefit from reduced downtime, minimized maintenance costs, and enhanced system reliability.

FAQs of Reconditioning HATR Plates:

Q: How is corrosion resistance restored during the reconditioning of HATR plates?

A: Corrosion resistance is restored by applying compatible alloys or protective coatings based on the plate material and the application environment. This ensures long-term durability in industries such as chemical processing, pharmaceuticals, and oil & gas.Q: What surfaces finishes are available for reconditioned HATR plates?

A: Plates can receive either a polished or brushed surface finish, depending on client requirements and specific operational needs. These finishes not only enhance appearance but also contribute to fouling resistance and ease of maintenance.Q: When should HATR plate reconditioning be performed?

A: Reconditioning is recommended when there is visible fouling, deterioration in thermal performance, corrosion, or plate deformation. The frequency depends on operational conditions and is typically performed on demand or as required to maintain system efficiency.Q: Where is this reconditioning service available?

A: Our reconditioning service is offered across India, catering to exporters, importers, manufacturers, suppliers, and traders who utilize heat exchangers in various industrial applications.Q: What is the process for restoring surface flatness and correcting warped HATR plates?

A: The process involves mechanical flattening techniques to restore original plate geometry, followed by surface finishing and reapplication of corrosion-resistant coatings if necessary. Each plate is returned to its proper specifications to ensure a complete seal and optimized thermal performance.Q: What are the benefits of reconditioning HATR plates instead of replacing them?

A: Reconditioning is cost-effective, extends the useful life of existing plates, quickly restores system efficiency, and reduces downtime compared to full replacement. It is also a sustainable choice, minimizing waste and resource consumption.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese Get A Quote

Get A Quote