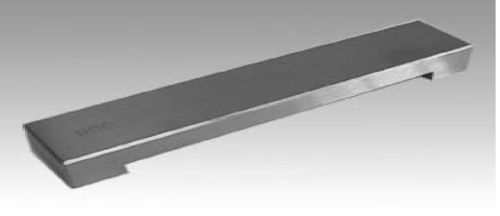

Cube Film Applicators

5000 INR

Product Details:

- Core Components Stainless Steel Applicator Block

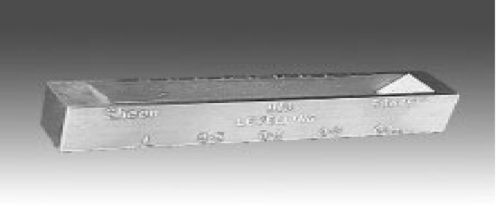

- Measurement Range 4 m to 14 m thickness

- Model No Cube Applicator Standard / Custom Sizes

- Power Source Manual

- Automation Grade Manual

- Accuracy High (Film thickness variation 1 m)

- Capacity 4, 6, 8, 10, 12, 14 m (microns), other sizes on request

- Click to view more

X

Cube Film Applicators Price And Quantity

- 5000 INR

- 1 Piece

Cube Film Applicators Product Specifications

- For precise and uniform application of films and coatings in laboratories

- Cube Applicator Standard / Custom Sizes

- Variable, typically 60 x 40 x 40 mm (standard cube)

- Provides constant film thickness with high reproducibility

- 4 m to 14 m thickness

- 4, 6, 8, 10, 12, 14 m (microns), other sizes on request

- Approx. 300 g (varies by model)

- High (Film thickness variation 1 m)

- Manual

- Stainless Steel Applicator Block

- Manual

- Cube Film Applicator

Cube Film Applicators Trade Information

- 5-10 Piece Per Month

- 6-8 Week

Product Description

Purchase the Latest Cube Film Applicators, designed for enlightened professionals seeking flawless results in laboratories. Featuring a Best-in-class mirror polish surface for easy cleaning, these precision applicators guarantee constant film thickness and high reproducibility. Suitable for glass, paper, plastic, and metal substrates, they require no lubrication and meet ASTM D823 standards. Customizations are available to suit every need, with micron ranges from 4 to 14 m. Supplied in a protective box for a Limited time, secure yours now and experience flawless uniform film application.

Versatile Application for Accurate Film Coating

Cube Film Applicators can be used on glass, paper, plastic, and metal substrates, making them highly adaptable for various laboratory conditions. These applicators distribute a range of application media, including coatings and films, with flawless consistency. To use, simply place the Cube Applicator on the clean substrate and draw it across the surfacemanual precision ensures even film thickness every time. Clean with solvent after each use for enduring Best performance.

Global Supply, Market Coverage, and Value

As a premier exporter, importer, manufacturer, supplier, and trader based in India, our Cube Film Applicators are highly valued in both domestic and international markets. We fulfill orders with prompt completion timelines, catering to buyers with specific customization requests at competitive asking prices. Our supply ability ensures there is no delay in delivery, maintaining the market value and reliability customers expect from an industry leader in laboratory film applicators.

Versatile Application for Accurate Film Coating

Cube Film Applicators can be used on glass, paper, plastic, and metal substrates, making them highly adaptable for various laboratory conditions. These applicators distribute a range of application media, including coatings and films, with flawless consistency. To use, simply place the Cube Applicator on the clean substrate and draw it across the surfacemanual precision ensures even film thickness every time. Clean with solvent after each use for enduring Best performance.

Global Supply, Market Coverage, and Value

As a premier exporter, importer, manufacturer, supplier, and trader based in India, our Cube Film Applicators are highly valued in both domestic and international markets. We fulfill orders with prompt completion timelines, catering to buyers with specific customization requests at competitive asking prices. Our supply ability ensures there is no delay in delivery, maintaining the market value and reliability customers expect from an industry leader in laboratory film applicators.

FAQs of Cube Film Applicators:

Q: How do I operate the Cube Film Applicator for best results?

A: Simply place the applicator on your clean substrateglass, paper, plastic, or metaland draw it smoothly across the surface to achieve a uniform film thickness. No lubrication is required, and the manual design allows for precise control.Q: What surfaces and materials can the Cube Film Applicator be used on?

A: This applicator is engineered for use on glass, paper, plastic, and metal substrates, making it suitable for various laboratory film or coating applications.Q: When should I clean the Cube Film Applicator and how?

A: Its best to wipe the applicator clean with a solvent immediately after each use. The mirror-polished surface allows for easy residue removal, ensuring long-term flawless performance.Q: Where do you export Cube Film Applicators from?

A: We export and supply Cube Film Applicators from India to international markets, fulfilling orders for labs worldwide.Q: What are the benefits of using this Cube Film Applicator over other types?

A: The stainless steel construction, mirror polish, high reproducibility, constant film thickness, and compliance with ASTM D823 standards make it a reliable, accurate, and easy-to-clean choice for laboratory professionals needing flawless results.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese Get A Quote

Get A Quote