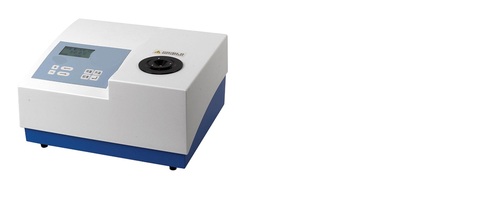

DURO LAB 432-1B DIGITAL MELTING POINT APPARATUS

5000 INR

Product Details:

- Automation Grade Semi-Automatic

- Voltage 230 V AC

- Frequency 50 Hz

- Power Source AC mains

- Capacity Up to 3 samples simultaneously

- Model No DURO LAB 432-1B

- Feature Rapid and precise measurement, Digital control, Built-in magnifier

- Click to view more

X

DURO LAB 432-1B DIGITAL MELTING POINT APPARATUS Price And Quantity

- 5000 INR

- 1 Piece

DURO LAB 432-1B DIGITAL MELTING POINT APPARATUS Product Specifications

- 230 V AC

- 50 Hz

- Semi-Automatic

- Up to 320C

- Digital LED Display

- DURO LAB 432-1B

- Rapid and precise measurement, Digital control, Built-in magnifier

- AC mains

- Digital Melting Point Apparatus

- Up to 3 samples simultaneously

- Heating block, Digital display, Temperature sensor, Capillary tube holder

- Approx. 3.5 kg

- Ambient to 320C

- 340 x 220 x 170 mm

- Powder-coated MS body, Glass capillary tube holder

- 1C

- Laboratory melting point determination

DURO LAB 432-1B DIGITAL MELTING POINT APPARATUS Trade Information

- 5-10 Piece piece Per Month

- 6-8 Week

Product Description

DURO LAB 432-1B DIGITAL MELTING POINT APPARATUSAdvanced Features for Accurate Melting Point Measurement

Designed with a digital control system, the DURO LAB 432-1B offers digitally adjustable ramp rates, a platinum RTD sensor for superior accuracy, and an integrated magnifying lens for close sample observation. The digital LED display shows temperature readings with 0.1C resolution, empowering users to monitor and record precise results for up to three samples simultaneously.

Efficient and Safe Laboratory Operation

This apparatus has a semi-automatic operating grade, providing audio-visual alarms to alert users when the set temperature is reached. Its powder-coated MS body and glass capillary tube holder enhance durability and sample safety. The natural convection cooling method facilitates seamless cycling between runs while maintaining laboratory safety standards.

Versatility for Various Laboratory Applications

Ideal for pharmaceutical, chemical, and research laboratories, the DURO LAB 432-1B suits routine melting point analysis and educational purposes. Its adjustable heating rate and broad temperature range make it compatible with multiple sample types and research scenarios, ensuring reliable performance across diverse laboratory environments.

FAQs of DURO LAB 432-1B DIGITAL MELTING POINT APPARATUS :

Q: How does the DURO LAB 432-1B Digital Melting Point Apparatus determine melting points?

A: The apparatus uses a precision platinum RTD sensor to monitor temperature rise as samples are heated in glass capillary tubes. Users observe sample changes through the built-in magnifying lens on a digital LED display, allowing accurate determination when samples reach their melting point.Q: What samples and applications is this melting point apparatus suitable for?

A: It is suitable for a variety of pharmaceutical, chemical, and academic research samples. The apparatus can analyze up to three solid samples simultaneously, making it ideal for laboratories needing efficient, reliable melting point determinations.Q: When should I use the ramp rate control feature and how is it adjusted?

A: Ramp rate control should be used when testing samples with specific melting characteristics. Users can digitally adjust the heating rate (up to 10C per minute) via the control panel, ensuring optimal conditions for both rapid and delicate measurements.Q: Where can this apparatus be installed within a laboratory setting?

A: With dimensions of 340 x 220 x 170 mm and a lightweight design (approx. 3.5 kg), the DURO LAB 432-1B fits easily on standard laboratory benches. Its robust build and safe operation allow placement in any regulated laboratory environment.Q: What is the process for running a melting point determination with this equipment?

A: Insert up to three samples in standard 1.4 mm glass capillary tubes into the holder, set your desired temperature and ramp rate, and start the run. Observe sample behavior through the magnifier and digital display. The apparatus will sound an audio-visual alarm when set temperatures are reached.Q: What are the benefits of the audio-visual alarm system during usage?

A: The alarm system promptly notifies users when the set temperature has been attained, preventing over-heating and ensuring consistent sample integrity. This feature increases laboratory safety and helps maintain measurement accuracy.Q: How does natural convection cooling enhance the melting point measurement process?

A: Natural convection provides gradual cooling between runs without the need for additional cooling equipment. This simplifies operation, shortens downtime, and allows users to quickly prepare for consecutive measurements, supporting efficient laboratory workflows.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese Get A Quote

Get A Quote