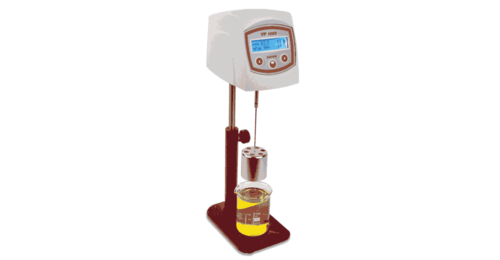

KU-2 Viscometer

Product Details:

- Sensor Type Rotational Sensor

- Equipment Type Paint and Coating Viscometer

- Connectivity Type RS232 Serial Port

- Capacity 500 ml (standard sample cup)

- Resolution 0.1 KU / 1 g / 1 cP

- Measurement Range 40141 KU (275274 cP)

- Frequency 50 Hz

- Click to view more

KU-2 Viscometer Price And Quantity

- 3 Piece

KU-2 Viscometer Product Specifications

- 10W

- 220V AC, 50Hz

- Rotational Sensor

- Paint and Coating Viscometer

- Stainless Steel & High-Impact Plastic

- 40141 KU (321099 g) (275274 cP)

- RS232 Serial Port

- 1% of full scale

- 500 ml (standard sample cup)

- 0.1 KU / 1 g / 1 cP

- 50 Hz

- Digital LCD Display

- 40141 KU (275274 cP)

- 85% RH (Non-condensing)

- 5C to 50C

KU-2 Viscometer Trade Information

- 3-4 Piece Per Day

- 3-4 Week

Product Description

KU-2 Viscometer

for Paints, Coatings, and Inks

ASTM D562 Compatible (industry specification)

Easy to use no weights, simplifies and established test procedure

LED Display Info:

-Krebs Units

-Gram Units (Weight)

-Centipose

Select Krebs or Grams or Centipoise

Lock-In Test Results with hold switch

Standard Krebs Spindle

Variable angle allows for greater viscosity range

Measurement Range: 40 to 141 KU, 32 to 1099 gm, and 27 to 5274 cP

Printer Connection for automatic test documentation

Adapter provided for pint, pint, and quart containers

Accuracy: 1.0% of range

Repeatability: 0.5%

Whats Included?

Instrument

Krebs-type spindle

Communications port for printer

Adapter for quart, pint and pint cans

Optional Accessories

Air Purge

Paste Spindle

Applications

Paints

Coatings

Adhesives

Inks

Pastes

Centipoise values based on the conversion from Krebs Units as defined in the ASTM D562. Adapters which accommodate metric size cans are available

Versatile Viscosity Measurement

Adapted for paints, coatings, and printing inks, the KU-2 Viscometer delivers accurate viscosity readings using various units, including KU, grams, and cP. The digital LCD display ensures results are easy to read, supporting a wide range of applications in quality assurance and production environments.

Intuitive Controls & Calibration

The instrument features a user-friendly membrane keypad and supports both automatic and manual calibration, making setup and operation straightforward. This user-centric design helps reduce operator error and ensures consistent measurement reliability.

Robust Design & Compliance

Constructed from stainless steel and high-impact plastic, the KU-2 Viscometer is built for durability. The device meets ASTM D562 standards for viscosity measurement, offering peace of mind for both manufacturers and regulatory bodies alike.

FAQs of KU-2 Viscometer:

Q: How do I use the KU-2 Viscometer for viscosity measurement?

A: To measure viscosity, pour your sample into the standard 500 ml ISO-certified cup, select the appropriate measuring unit on the digital display, and start the device using the membrane keypad. The paddle spindle automatically determines viscosity in KU, g, or cP according to your selection.Q: What calibration options are available with this viscometer?

A: The KU-2 Viscometer provides both automatic and manual calibration options. Automatic calibration simplifies routine checks, while manual calibration allows for adjustment to specific standards or sample types, helping maintain high accuracy in results.Q: When should I perform recalibration of the viscometer?

A: Calibration should be performed regularly, depending on usage frequency and quality requirements. Its recommended to recalibrate after major maintenance, when switching sample types drastically, or if unusual readings are observed.Q: Where can the KU-2 Viscometer be utilized?

A: This viscometer is ideal for laboratories, manufacturing facilities, and quality control departments in industries dealing with paints, coatings, and printing inks. Its compliance with ASTM D562 ensures suitability for both R&D and production settings.Q: What benefits does the paddle-type spindle provide?

A: The paddle spindle is particularly effective for materials with moderate to high viscosity, such as paints and inks, ensuring representative and reproducible mixing during measurement for accurate viscosity determination.Q: How does the digital LCD display enhance usage?

A: The clear, backlit LCD digital display provides direct readout of viscosity measurements, minimizing interpretation errors and improving workflow efficiency, especially in high-throughput environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese Get A Quote

Get A Quote