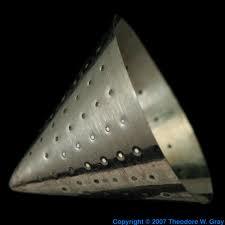

Platinum Foils

5000 INR/Piece

Product Details:

- Temperature Resistance Up to 1768C (Melting Point)

- Accuracy High Purity, Chemically Stable

- Features Corrosion Resistant, High Melting Point, Malleable, Chemically Inert, Smooth Surface

- Shape Sheet/Foil

- Type Platinum Foils

- Dimension (L*W*H) Customized / As per requirement

- Equipment Type Foil / Sheet

- Click to view more

X

Platinum Foils Price And Quantity

- 3 Piece

- 100.00 - 1000.00 INR/Piece

- 5000 INR/Piece

Platinum Foils Product Specifications

- Foil / Sheet

- Laboratory, Research, Industrial Applications, Catalysis

- Platinum

- 99.95% Pure Platinum

- Up to 1768C (Melting Point)

- Customized / As per requirement

- Corrosion Resistant, High Melting Point, Malleable, Chemically Inert, Smooth Surface

- Sheet/Foil

- High Purity, Chemically Stable

- Platinum Foils

Platinum Foils Trade Information

- MUMBAI

- Telegraphic Transfer (T/T), Cash in Advance (CID), Cash Advance (CA)

- 3-4 Piece Per Day

- 3-4 Week

- All India

- ISO CERTIFICATION

Product Description

| No. | Thickness mm | Weight gram / 100 sq cm |

| NAC 144A | 1.00 | 214 |

| NAC 144B | 0.90 | 192 |

| NAC 144C | 0.80 | 171 |

| NAC 144D | 0.70 | 149 |

| NAC 144E | 0.60 | 128 |

| NAC 144F | 0.50 | 107 |

| NAC 144G | 0.40 | 86.50 |

| NAC 144H | 0.30 | 64.20 |

| NAC 144I | 0.25 | 53.50 |

| NAC 144J | 0.20 | 42.80 |

| NAC 144K | 0.15 | 32.15 |

| NAC 144K | 0.10 | 21.40 |

Exceptional Performance in Extreme Conditions

Platinum foils provide outstanding resistance to high temperatures and corrosive chemicals, retaining integrity even at 1768C. This resilience makes them indispensable for laboratories, industrial research, and catalytic environments, where stability and durability are paramount.

Precision Customization and Safe Packaging

Available in custom thicknesses and dimensions, these platinum foils can be tailored to meet specific requirements. Each order is securely packaged using protective measures, ensuring the material arrives in pristine condition for immediate use.

Superior Material Properties for Diverse Applications

Featuring a high degree of purity (99.95%), smooth surface, and malleable structure, platinum foils are well-suited for scientific instrumentation, high-tech manufacturing, and catalytic converters. Their chemical inertness ensures reliability across varied applications.

FAQs of Platinum Foils:

Q: How can I request customized dimensions and thickness for platinum foils?

A: You can specify your required dimensions and thickness when placing your order. The manufacturer accommodates customization, offering thicknesses from 0.05 mm to 1 mm and tailored length and width according to your needs.Q: What are the primary benefits of using platinum foils in industrial and laboratory environments?

A: Platinum foils offer high purity, excellent tensile strength, resistance to corrosion, and stability at very high temperatures. These features make them ideal for sensitive research, catalysis, and harsh industrial settings.Q: Where are platinum foils typically used?

A: These foils are commonly utilized in laboratories, research facilities, industrial settings, and catalytic processes, owing to their chemical inertness and robustness at elevated temperatures.Q: What process ensures the purity and quality of platinum foils?

A: The platinum foils undergo strict manufacturing controls and testing to guarantee purity levels of at least 99.95%. Advanced refining techniques and precise rolling processes maintain high quality and surface smoothness.Q: How is the platinum foil packaged to guarantee safe delivery?

A: Each platinum foil is securely packed in protective materials that guard against physical damage, contamination, and environmental exposure during shipping, ensuring the product reaches you in optimal condition.Q: What is the temperature resistance of these platinum foils, and why is it important?

A: Platinum foils can withstand temperatures up to their melting point of 1768C. This high temperature resistance is crucial for applications requiring stability under intense heat, such as catalysis or high-temperature experimental setups.Q: Can platinum foils be used for catalytic applications, and what makes them suitable for this use?

A: Yes, platinum foils are excellent for catalysis due to their superior chemical inertness, high purity, and ability to resist corrosion and degradation, even during prolonged exposure to reactive environments.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese Get A Quote

Get A Quote