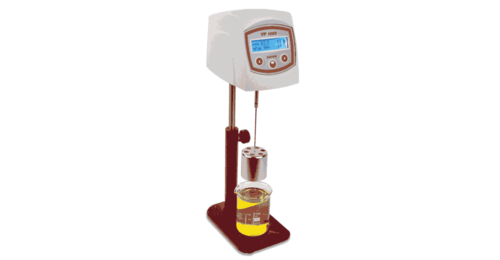

VTA Pneumatic Viscosel

150 INR/Piece

Product Details:

- Equipment Type Pneumatic Viscosel (Pneumatic Viscosity Measuring Equipment)

- Resolution High, Depends on Model

- Temperature Range Ambient (Special Models for Elevated Temperatures)

- Capacity Standard Lab and Process Capabilities

- Humidity % 0 95% RH Non-condensing (Operational)

- Pressure Range Up to 7 Bar (100 psi) Air Supply

- Measurement Range 10 100,000 cP (centipoise)

- Click to view more

X

VTA Pneumatic Viscosel Price And Quantity

- 3 Piece

- 150 INR/Piece

- 100.00 - 1000.00 INR/Piece

VTA Pneumatic Viscosel Product Specifications

- 10 100,000 cP (centipoise)

- Depends on Viscosity and Model

- Pneumatic Output, Analog Signal Possible

- Compressed Air Driven

- Rotational Pneumatic Viscosity Sensor

- No Display (Pneumatic Analog Output)

- Varies by Model (Typically up to 100,000 cP)

- 0 95% RH Non-condensing (Operational)

- Up to 7 Bar (100 psi) Air Supply

- Stainless Steel, Aluminium, Engineering Plastics

- Standard Lab and Process Capabilities

- Ambient (Special Models for Elevated Temperatures)

- 1% FS (Full Scale)

- Pneumatic Viscosel (Pneumatic Viscosity Measuring Equipment)

- High, Depends on Model

VTA Pneumatic Viscosel Trade Information

- MUMBAI

- 3-4 Piece Per Day

- 3-4 Week

- All India

- ISO CERTIFICATION

Product Description

The VTA-120 includes viscosity indication and control in one complete package and is widely used on line in the printing and coatings industries for automatic addition of solvents. The Viscosel is a pneumatic viscosity indicator for inexpensive viscosity control in explosion proof environments.

Features And Benefits

- Convenient & Inexpensive

- Viscosity measurement and control combined in one compact package that mounts easily to process equipment on the production floor. Operating method uses the well-accepted coaxial cylinder principle of viscosity measurement.

- Responsive

- The Viscosel®'s sensitive response and automatic operation assures continuous conditioning of fluid.

- Measures In-line

- Eliminates time constraints associated with viscosity analysis of grab samples in the laboratory; provides early detection and correction of in-process deviations from desired set points.

- Quality Control

- Decreases raw material and product waste; maintains control of desirable product qualities (coating thickness, ink printability, % solids, etc.)

- Easy to clean

- Only the measuring cylinder and sample chamber come in contact with the sample. They can be easily cleaned or - if necessary - replaced without re-calibration.

- Easy to Change Range

- Measuring cylinders hook on and off easily, without tools and without need to adjust the instrument.

- Standard or Custom Mounting

- Using the standard mount, the Viscosel® can be moved wherever and whenever required. Custom bracket, cart, and tank mounts are available

- ±1% accuracy full scale

- The Viscosel® is guaranteed to be accurate within ±1% of the range in use and reproducible to ±0.5% of full scale range.

- Easy-to-read viscosity indication

- The easily read set point mark and viscosity indicator are in parallel when the instrument is on control, making possible a quick visual check, even from a distance.

- Safe pneumatic operation

- The Viscosel® and its drive, the indicator/controller and the valve for solvent addition are all pneumatically operated, without complex electronic circuits.

- Finely modulated control

- The Viscosel® system offers on/off pneumatic control with 1% throttling action. Whether working with inks, coatings or lacquers, the instrument maintains constant viscosity by controlled solvent addition. The viscometer is also available as a transducer only.

Specifications

- Range: 0-35 cP min 0-2000 cP max

- Output: 0-15 psig to solvent valve; 3-15 psig linear signal proportional to viscosity to receiver gauge and optional recorder

- Input Air: 20-22 psig regulated input; 3 scfm consumption max.

- Flow: Sample chamber requires 1 gpm max.

Applications

| Low Viscosity | |

| Adhesives, solvent based | Chemicals |

| Oils | Petroleum Products |

| Paints, Inks, Coatings | Polymers |

Flexible Mounting & Operation

Choose between flange or inline mounting for seamless integration into your process line. The VTA Pneumatic Viscosel is adaptable for both continuous monitoring and batch measurements, accommodating diverse industrial needs such as paints, coatings, and chemicals.

Exceptional Reliability & Safety

Designed for hazardous areas, explosion proof variants increase workplace safety. The absence of electrical parts in the sensor head and minimal maintenance requirements provide reliable, long-term operation even in rigorous industrial settings.

Effortless Maintenance & Cleaning

The Viscosel simplifies maintenance due to its pneumatic operation, and easy cleaning capabilities. Select models provide clean-in-place (CIP) or sterilize-in-place (SIP) options, supporting hygienic applications like food processing or pharmaceuticals.

FAQs of VTA Pneumatic Viscosel:

Q: How is the VTA Pneumatic Viscosel installed in an existing process line?

A: The device offers both flange and inline mounting options, allowing straightforward integration into your process. Standard mounting clamps and connection kits are provided for quick and secure installation in most production setups.Q: What are the output signal options for the Viscosel, and how is data transmitted?

A: By default, the Viscosel provides a pneumatic output. An analog 420 mA signal is available as an option via a pneumatic/electronic converter, enabling integration with industrial monitoring and control systems.Q: When should the Viscosel be chosen for viscosity measurement in hazardous areas?

A: Select the VTA Pneumatic Viscosel when operating in potentially explosive or hazardous environments, as explosion proof models are available which comply with rigorous industrial safety standards.Q: Where can the Viscosel be used across different industries?

A: It is suitable for use in paints, coatings, chemicals, oils, and food processing, among others. The construction materialsstainless steel, aluminum, and engineering plasticsenable compatibility with a wide range of fluids.Q: What is the process for cleaning and maintaining the device?

A: Routine maintenance is minimal due to the pneumatic design with no moving electrical parts. Cleaning is straightforward, and select models offer clean-in-place (CIP) or sterilize-in-place (SIP) capability, further reducing process downtime.Q: How does using this viscosel benefit industrial operations?

A: Its high measurement accuracy (1% full scale), broad range (10100,000 cP), robust construction, and explosion proof options enhance process control, reliability, and operator safety, ultimately improving product quality and efficiency.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese Get A Quote

Get A Quote